BEST OLIVE OIL IS MADE BY HAND

“Our organic olive oil production”

THE SECRET OF GOOD OLIVE OIL LIES …

… in processing. Quality is not magic. Our olive oil is one of the best in the world, simply because we know and respect the handling of our fruit from an old family tradition. In production, we follow our grandfather’s rule:

“You can only harvest as much as you can process in one day”..

The same day, the harvested olives are taken to the mill, cleaned, washed and pressed, and the resulting olive oil is immediately filled into air- and light-tight stainless steel tanks. This is the only way to ensure that the best ingredients in the olive remain unchanged. And there are many indeed.

Our olive oil mills:

Quality is produced in-house!

Many smaller olive oil producers have a problem: they have to take their olives to an external oil mill to extract their oil!

At that point, they lose control of their own product. You may be lucky and find a partner who takes care of your system and keeps it clean. But usually it is different. At harvest time, many oil farmers come all at once with their olives and there are queues. Apart from the fact that the olives have to be kept longer, the miller is also stressed. In this situation, the machines run at full speed and maintenance, cleanliness and especially temperature control become a secondary activity.

These and many other reasons motivated us to invest in our own system, as this was the only way to control the production process to the end.

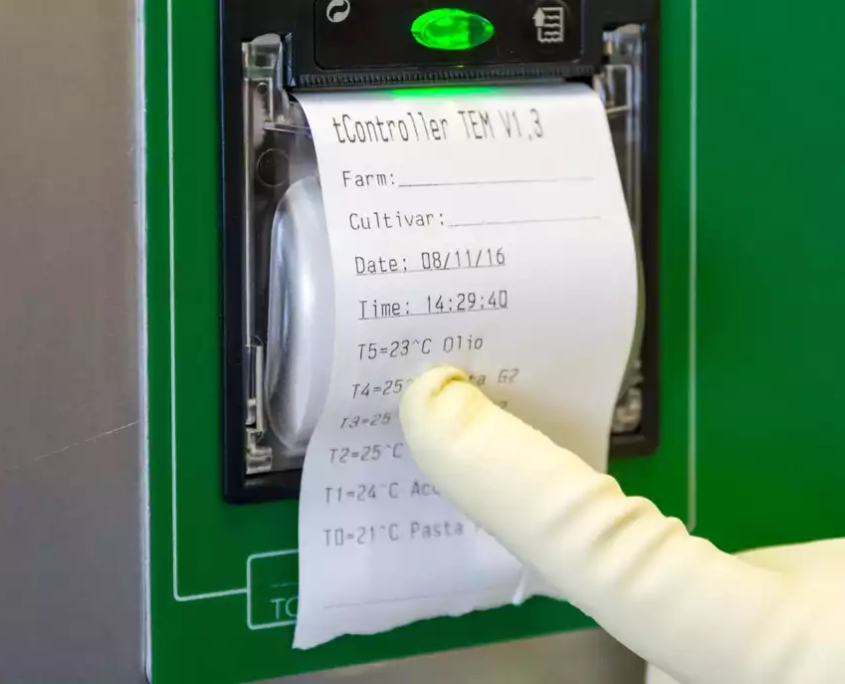

From that moment on, we have been able to get the best out of the starting product olive. Our system is one of the most modern in the field of oil mill technology (“Toscana Enologica Mori”) and is only used by high-end producers. The closed system allows us to work in a process that excludes any oxidation process on the olive paste, starting with the leaf separation process and the washing of the olives. The temperature is constantly under control and consistently falls below each maximum standard (27°). After filtering, the olive oil comes into contact with oxygen for the first time and is then bottled in airtight stainless steel tanks. The final process, bottling, also takes place in an airtight manner in our own bottling plant.

The extraction process

Olive oil production according to all rules of the art

It is important that the olives do not lie too long before they are crushed. From the tree, they continue their life for several dozen hours (depending on the conditions). Then the quality of the product immediately begins to deteriorate. Therefore, our olives are processed within 10/24 hours (depending on the type of oil). After removing excess leaves and twigs, they are washed in fresh water.

Then, avoiding increasing the temperature and pulverising the core, the olives are finely ground in a knife press.

Antioxidants and polyphenols

The greatest enemy in oil processing is oxidation. To avoid it, an absolutely closed processing line is essential, only in this way can we extract the highest values of the most valuable substances, antioxidants and polyphenols, from our olives.

Why not traditional?

With the press mat method…

In the choice traditional handcrafting has advantages. In the production of the oil, the situation is different, the experts agree. That is why we process the olives in a modern way without exception. One reason for this is that the traditional method with stone mills and press mats increasingly leads to pulverisation of the kernel and strong oxidation processes. In addition, the risk of contamination is very high due to this method.

Why do we filter the oil?

The naturally cloudy olive oil looks so beautiful…

Of course, freshly pressed and naturally cloudy olive oil looks very tasty, but appearances can be deceptive. After a while, the turbid substances settle and become too modern. They then give the oil a rancid and bitter taste. Wholesalers’ naturally cloudy oil is intended to suggest to consumers that it is a natural product, but in reality it is manipulated.

Our oil is filtered after extraction from the decanter without further manipulation. First, it passes through a stainless steel micro filter with a micro diatomaceous membrane and then a special paper filter. The former removes only the coarser impurities, while the latter finally removes the very finest.

Why the dark bottles?

It is so beautiful when you can see the colour of the oil …

You look through the white glass and see a bright yellow or green olive oil… a real beauty! But far from it. Anyone who tries to lure consumers in this way is only doing their wallet a favour! For there are two cases: either the olive oil with its beautiful colour is not such a good oil at all, so it does not matter if it has been lying in the light on the shelves for weeks, or the producer simply does not care if his good oil starting product is spoilt in the light. Hands off in any case! Light is the #1 enemy of an olive oil and it spoils it very quickly, only buy oil in dark or black bottles.

Bus and bag in box

Both have their place

The bag-in-box is a novelty when it comes to olive oil. The olive oil can be drained without coming into contact with oxygen or light; the bag inside collapses and closes the more oil is drained without coming into contact with oxygen. We are an organic company and attach great importance to sustainability, avoiding plastic is one of the criteria the bag-in-box meets, it consists of only 8% plastic (but must be recyclable). The sheet steel jerry can is 95% recyclable and optimally protects the olive oil from light. In terms of taste, the can does not give off any oil and the bag in the BiB is also food-neutral.